VIDEO STAND INSPECTION (VSI)

Directly on the monitor (without PC) you can view, zoom, measure, compare, capture video and archive everything you see. The new VSI system does all this, and can be used with ease even by staff not familiar with these instruments. Unique in its category (quality/price ratio), it can be advantageously used even in very small companies.

The great flexibility allows you to remove the video head of the VSI in a few seconds (without any tools) and place it on the mobile stand VSI mini to be transported outside the usual workstation. If connected to a computer, you can also perform many other functions thanks to our dedicated software.

The VSI system, thanks to its characteristics, is perfect to be used in hard conditions, where the computer could be an obstacle or the operator distracted by tasks not compatible with his usual tasks. The VSI is a fairly simple and practical tool, it can perform quick sample inspections during production, with the possibility to inspect details of any type of object superficially or internally (small cracks or holes from 2mm diameter up). Small objects can also be held by the fingers under the video head, the monitor acts as a variable magnifying glass (15➜22X optical zoom and 22➜80X digital zoom). Even parts of very bulky and heavy objects (e.g. castings parts, moulds, etc.) can be successfully inspected by attaching the VSI stand to a wall so that a sliding table can be placed underneath it.

The VSI system can be connected to any monitor on the market, with 1280x720 or 1920x1080 pixel resolution.

Here are the main functions of the system, when connected to the monitor only:

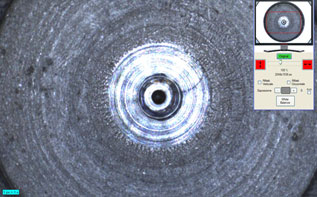

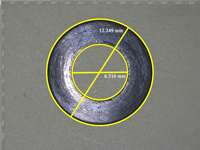

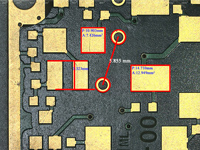

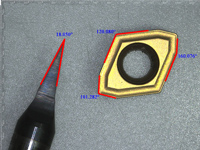

- Magnify and measure the parts of main interest during the manufacturing, with the tools for measuring lines, rectangles, circles, angles, polygons, ellipses, arcs of circle.

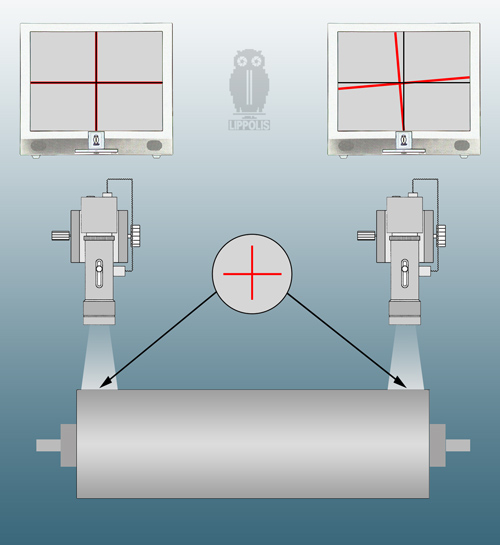

- Insert on the image single or multiple pairs of axis for measurement and sample check in production.

- Compare images, superimposed or half screen.

- Capture images on an SD card for storage and review in your PC, with or without measurements.

- ...and many other functions, customizable by each user.

PC/Laptop connection

The VSI can be connected directly to a PC/Laptop by USB2.0 cable expanding its functions and possibilities to use. Everything will become easier and faster, with additional and more accurate measurements thanks to our Video View Light software.

It will be also convenient to use only the video head by unhooking it from the VSI maxi when you need the portability of your system to do the same checks outside the usual workstation. For this purpose, using a normal laptop PC and a kit specially prepared by us, the video head of the VSI can be equally functioning on a mini-stand and thanks to a rechargeable lithium battery at least 4 hours of consecutive work will be ensured. The supplied aluminium case guarantees the transportability of our kit.

The system with the Video View Basic software (more performing than the Video View Light) can do also:

- Assisted focus control;

- All common types of measurements;

- The application of tolerances;

- Transparent superimposition of an image or a CAD drawing on the video.

APPLICATION EXAMPLES

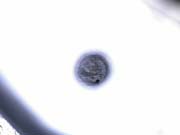

The system is particularly suitable to make inspections and controls inside holes and grooves also with elevated depth.

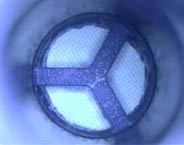

In the proposed example is shown a cork of pen long about 40mm with inside hole of 8mm of diameter.

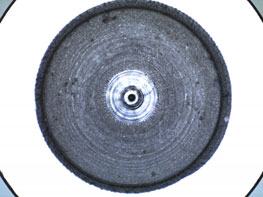

In the photos the conformation of the bottom of the cork, the astringent collar of the inside wall and the superior surface of the thickness of the walls are visible.

Since these systems have been studied for being directly used in the department of production, the system is simple, reliable and deprived of maintenance, the controls can be quickly effected by the personnel being also suitable to the production holding in a hand the specimen to be examined and rotating it under the auto-illuminating optic system.

|

Sample views with digital zoom inside small and deep holes  |

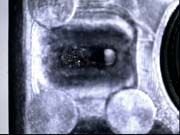

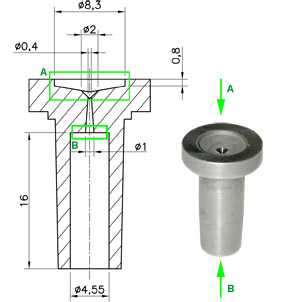

Registering a print matrix  |